AFM for Phase Imaging

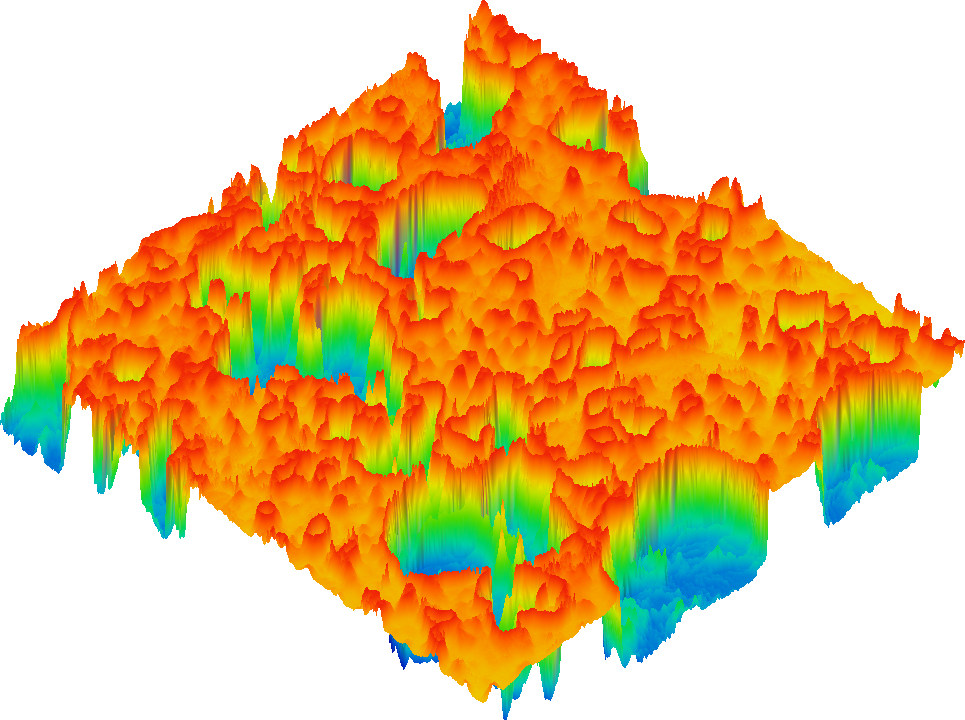

Common in everyday life, composite materials are used in a number of applications ranging from aerospace, automotive, electronics, and biomedical. Being able to perform analysis on composite materials and understand their structures and properties on the nanoscale is essential for optimizing their performance and designing better products. Small changes in composition and distribution can have dramatic effects on the final properties of these materials. Atomic Force Microscopy (AFM) is a game-changer since it can not only provide topographical data but also phase imaging analysis examining changes in mechanical and chemical properties.

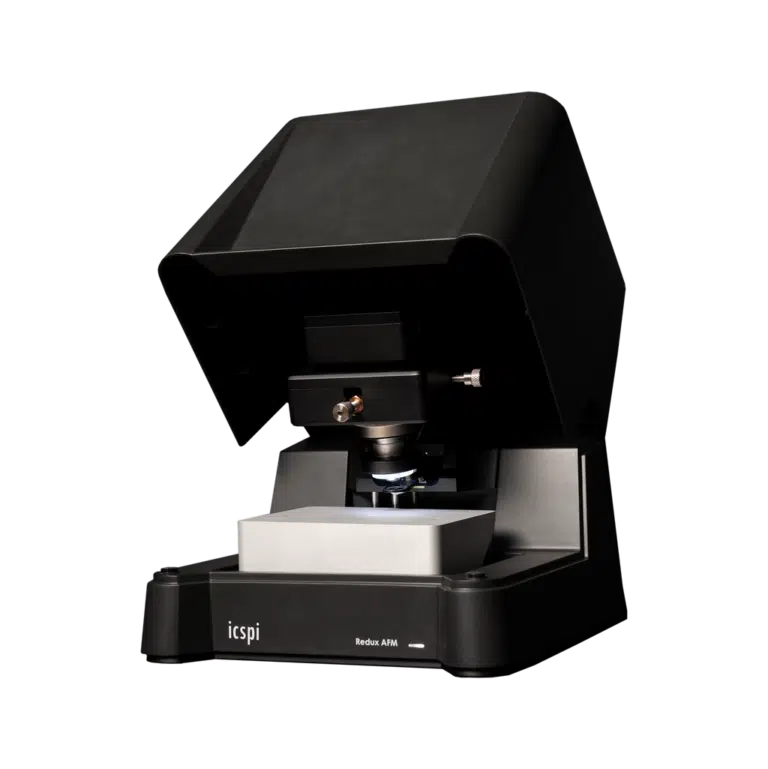

How can AFM provide such analysis? By measuring the mechanical interaction between the tip and sample, AFM can look at the phase shift: the lag between the driving and feedback signals. This produces phase contrast images that reveal differences in material stiffness, viscoelasticity, and adhesion. Regions with different material properties can be distinguished using the contrast of the phase image. Since the topography image and the phase image are generated at the same time, analysis of both images side by side can reveal information that might be hidden from just the topography image alone. This information is invaluable for understanding material behavior under different loading conditions, identifying regions of stress concentration, and optimizing material properties for specific applications. In this field, the nGauge and Redux Atomic Force Microscopes stand out, marrying unmatched precision, adaptability, and ease of use when combining topography and phase analysis.

Techniques such as optical microscopy, attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy, or scanning electron microscopy (SEM) can offer some functionality in phase analysis but are restricted by various limitations. Optical microscopy is limited in its ability to resolve anything below the order of 100s of nanometers. ATR-FTIR can provide a concentration number, but does not provide an actual map of the quantitative spatial distribution. SEM is not capable of measuring non-conductive samples and metallizing the surface would prevent investigation of the distribution of the components. AFM allows imaging of samples in their native state at high resolution, enabling accurate characterization without compromising the material’s integrity.

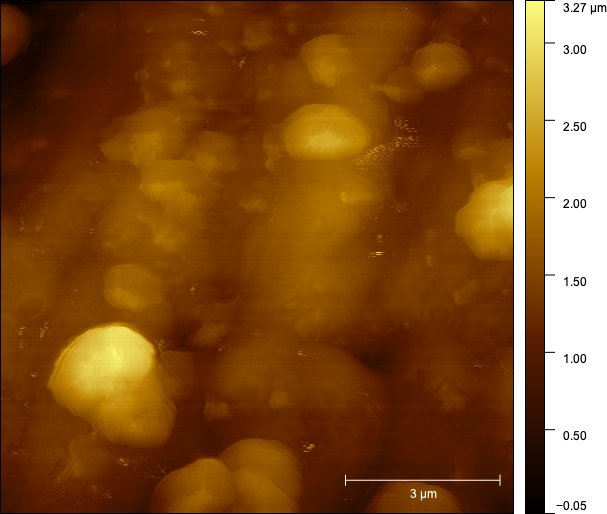

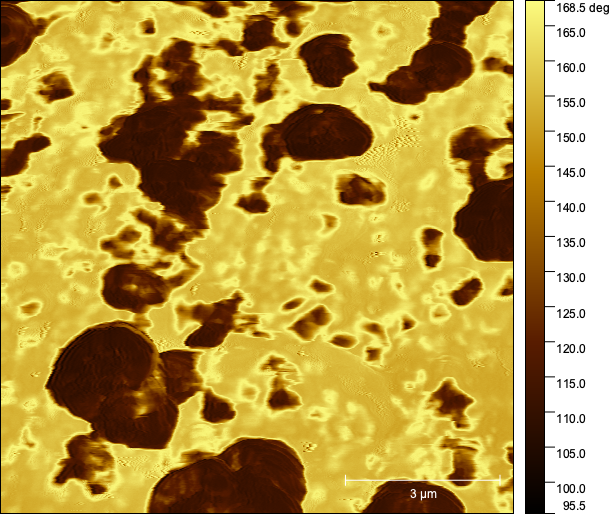

The effectiveness of our AFMs in phase analysis is exemplified through an analysis of a silica-polymer composite. Here is presented both a topography image as well as a phase image.

On the left, you can see a few particles that are protruding from the surface. They are bright in the topography image because they are the tallest features but it is unclear what the structure or morphology is of the rest of the image. The phase image on the right makes it clear which areas are silica: the dark areas represent regions with a low phase shift (around -50°). The light areas possess a much higher phase shift (around 30°) and they represent the polymer matrix. This is because each material possesses very different properties from each other. Through this example, we can see how AFM enables a deeper exploration of the intricate surface roughness of a sample.

In conclusion, AFMs are outstanding tools for phase analysis especially when combined with topographical data. Their advanced capabilities in capturing detailed three-dimensional surface data and material properties, along with the precision and user-friendliness of our models, make them crucial instruments for scientific research and industrial applications.

Our AFMs – the nGauge and Redux – surpass and complement traditional techniques in providing richer, more accurate data, and enhance the efficiency and reliability of phase analysis, solidifying their role as critical technologies in the field of nanoscale material investigation.

Compared to legacy AFMs, our systems provide much faster time-to-data combined with greater ease of use in a small form-factor. Our systems do away with traditional laser alignment and manual approach systems in favour of an automated micro-electromechanical-based system (MEMS) that greatly reduces the burden on the user. Our AFMs can live right on your benchtop and unlock your full capabilities.

Speak with an expert

Interested to learn more about how AFM phase imaging can provide insight on the composition of your samples at the nanoscale?