AFM for Nanoparticles Analysis

Nanoparticles are increasingly being used across a wide range of commercial and research fields including medicine, energy storage and materials engineering. Their ability to enhance and change apparent physicochemical properties of materials makes it an exciting growth area.

While typically defined as materials with sizes ranging between 1-100 nm, nanoparticles can come in all different shapes and sizes and be made from many materials, and also embedded within other materials, such as with nano-composites. Nanoparticles can be synthesized using a wide range of different production methods which include ‘bottom-up’ synthesis methods such as atomic condensation and laser pyrolysis, or through ‘top-down’ methods like mechanical or chemical etching.

Measuring and analyzing nanoparticles is critically important in many scientific and industrial applications, as it provides essential insights into product performance and the quality of manufacturing steps, leading to improvements in process control and cost-effectiveness

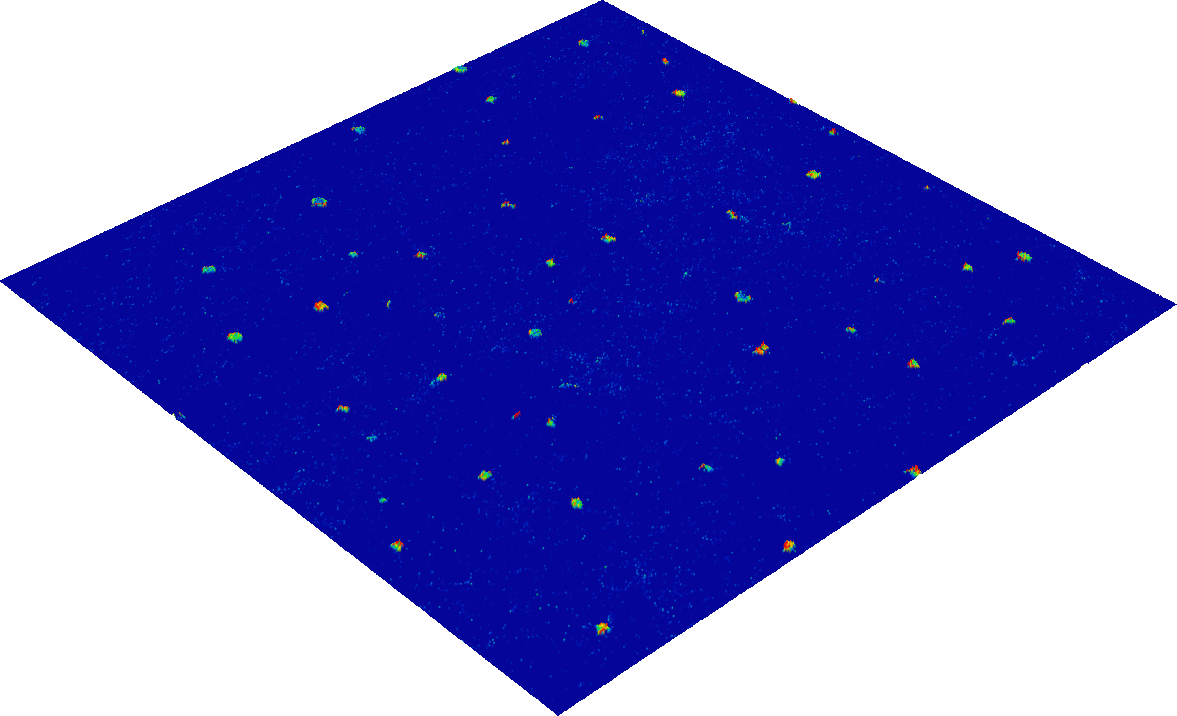

Atomic force microscopy (AFM) is a technique which can be used to gain topographical information about almost any kind of nanoparticle regardless of material or construction method. Using AFM allows for high resolution three-dimensional imaging of nanoparticles in a scan area which can be used to determine particle shape, size, and aspect ratio as well as statistical quantities such as various distributions.

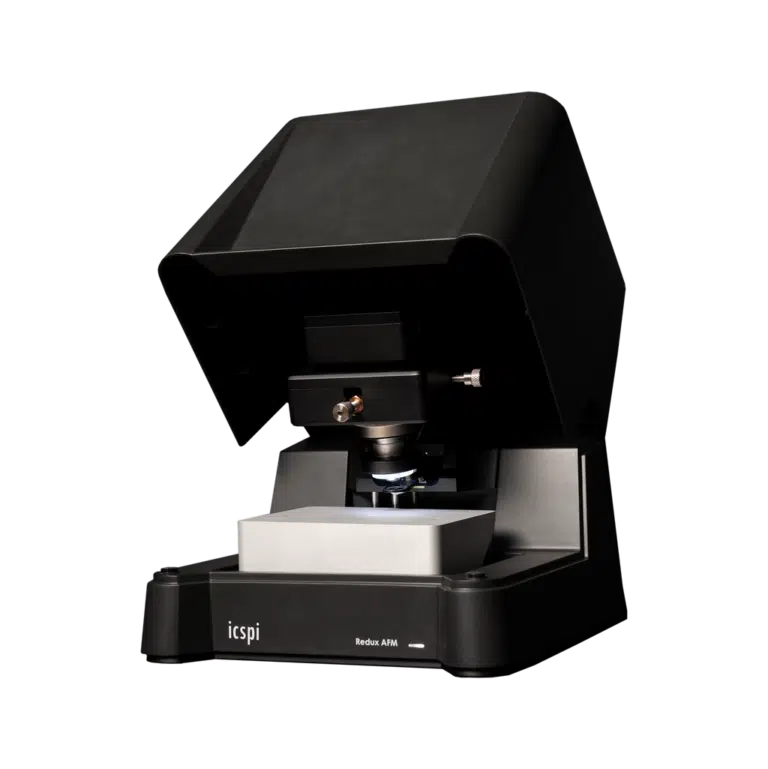

While other more specialised techniques such as SEM and TEM are available for examining nanoparticles, the Redux and nGauge AFMs offers a significantly easier and more affordable path to acquiring high resolution data. Complementary techniques such as SEM require advanced sample preparation such as sputtering to coat non-conductive samples before any imaging is possible which vastly increases the time-to-data. Other techniques such as DLS are also useful for particle analysis but are limited by their detection limit as well as their ability to give three-dimensional data and particle shape information. Line profiling can also be used to analyze particles but this technique is only feasible for particle amounts in the single digits and often does not provide robust data.

| AFMs | DLS | SEM | TEM | |

|---|---|---|---|---|

| Detection Limit (nm) | ~0.1 (Z) | 3 | 1 | ~0.1 |

| Requires Trained Operator? | ✔ or ✖* | ✖ | ✔ | ✔ |

| Sample Preparation Time | Fast | Fast | Slow | Slow |

| Measurement Medium | Air/Vacuum/Liquid* | Liquid | Vacuum | Vacuum |

| Time to Data | Fast to Slow* | Fast | Slow | Slow |

| Particle Shape Information | ✔ | ✖ | ✔ | ✔ |

| 3D Data? | ✔ | ✖ | ✖ | ✖ |

| Cost | $ to $$* | $ | $$ | $$$ |

In contrast, AFMs excel at providing detailed three-dimensional topographical information in an area. This is particularly beneficial when examining nanoparticles, as it allows for a comprehensive understanding of particle size and location distribution. Such thorough data is crucial in a range of applications, from food and beverage production to materials science research.

The proficiency of our AFMs in nanoparticles analysis is demonstrated when looking at these silver nanoparticles (Ag NPs). With the data available, we are able to easily see key details such as the average size of the particles being 100 nm as well as collect information regarding their shape, quantity, and distribution.

In summary, AFMs are formidable instruments for the measurement of nanoparticles. Their advanced capabilities in delivering detailed three-dimensional topographical data, combined with precision and ease of use in our products, make them essential tools for both scientific research and industrial applications.

Our AFMs – the nGauge and Redux – surpass traditional techniques in providing richer, more accurate data, and enhance the efficiency and reliability of nanoparticle measurements, solidifying their role as critical technologies in the field of nanoscale material analysis.

Compared to legacy AFMs, our systems provide much faster time-to-data combined with greater ease of use in a small form-factor. Our systems do away with traditional laser alignment and manual approach systems in favour of an automated micro-electromechanical-based system (MEMS) that greatly reduces the burden on the user. Our AFMs can live right on your benchtop and help you unlock your full capabilities.

Speak with an expert

Interested to learn more about how AFM can provide insight on your particles at the nanoscale?