AFM for Polymers and Composites

Atomic Force Microscopy (AFM) plays an important role in the analysis of polymers and composites. AFM has emerged as a vital technique for understanding the surface morphology, mechanical properties, and behavior of these materials at the nanoscale.

Polymers and composites play a crucial role in numerous industries, including aerospace, automotive, electronics, and biomedical. To optimize their performance and design advanced materials, it is essential to understand their structure and properties at the nanoscale level. This is where AFM steps in as a versatile and powerful tool.

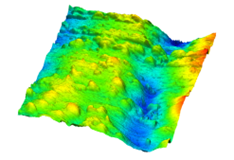

One of the key advantages of AFM is its ability to provide high-resolution topographical imaging. By employing a sharp probe to scan the sample surface, AFM generates three-dimensional maps of surface features with sub-nanometer-level precision, allowing researchers to examine surface roughness, texture, and morphology. This information is critical for understanding the interfacial behavior, adhesion, and surface interactions of polymers and composites. With AFM, researchers can observe even the finest details, such as surface defects, cracks, or aggregates, which may influence the material’s performance and durability.

Additionally, AFM’s phase imaging capability is a game-changer for the analysis of polymers and composites. This mode allows researchers to investigate variations in the mechanical and chemical properties across the sample surface. By measuring the mechanical interaction between the tip and sample, AFM collects phase contrast images that reveal differences in material stiffness, viscoelasticity, and adhesion. This information is invaluable for understanding material behavior under different loading conditions, identifying regions of stress concentration, and optimizing material properties for specific applications.

AFM offers a non-destructive imaging technique, which is particularly advantageous when dealing with delicate polymer samples. Standard nanoscale microscopy techniques like scanning electron microscopy (SEM) often require sample preparation techniques that may alter the surface properties or introduce artifacts, especially for polymers and composites. In contrast, AFM allows imaging of samples in their native state, enabling accurate characterization without compromising the material’s integrity. This capability is especially crucial for studying composite materials, where the interplay between different constituents and interfaces defines their overall properties.

In summary, AFM, with its topography and phase imaging capabilities, revolutionizes the analysis of polymers and composites. It provides high-resolution surface imaging, reveals nanoscale features and defects, enables the characterization of mechanical and chemical properties, and offers non-destructive analysis. By harnessing the power of AFM, researchers and engineers can gain valuable insights into the structure-function relationship of polymers and composites, leading to the development of superior materials with enhanced performance and functionality in various industrial applications.

Download App Note

Interested to learn more about how AFM can provide insight at the nanoscale on your polymer and composite samples?