Sensor-Integrated AFM Chips

Micro Sensors, Macro Benefits

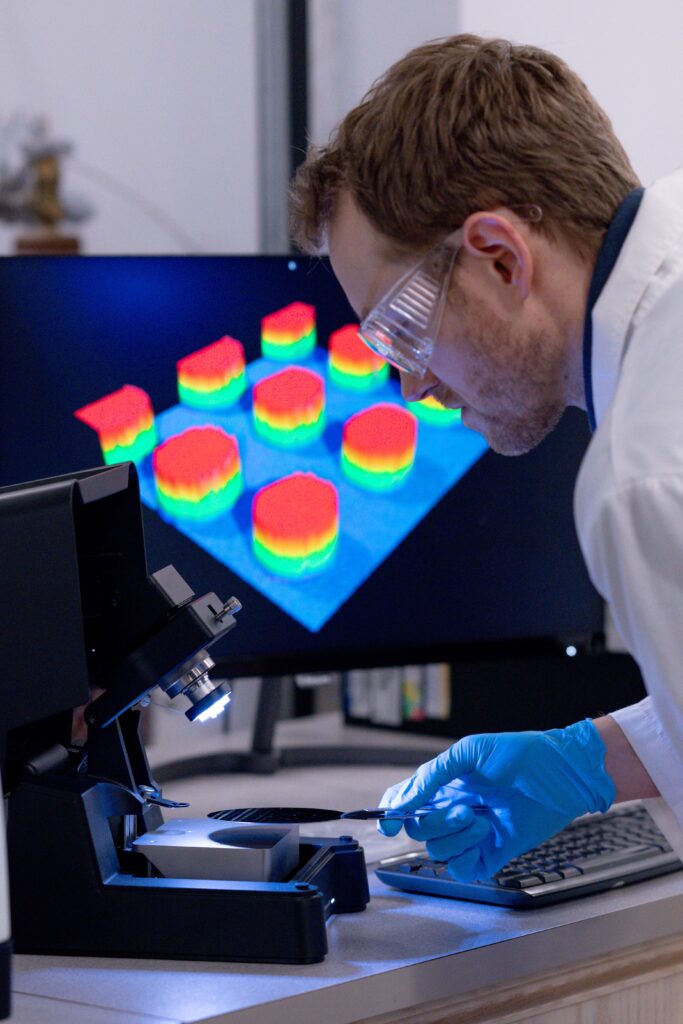

Built-in sensor technology eliminates the need for laser alignment and manual adjustments, focusing your attention on research, process development and quality control.

Durable Tips, Gentle Scans

Far surpassing the typical lifespan and cost-per-scan of traditional silicon tips, our chips have significantly extended tip life of over 1,000 scans without noticeable wear.

Preserve your samples thanks to the non-destructive interaction between the tip and the sample due to the built-in sensor.

What our users are saying

Tip Specifications

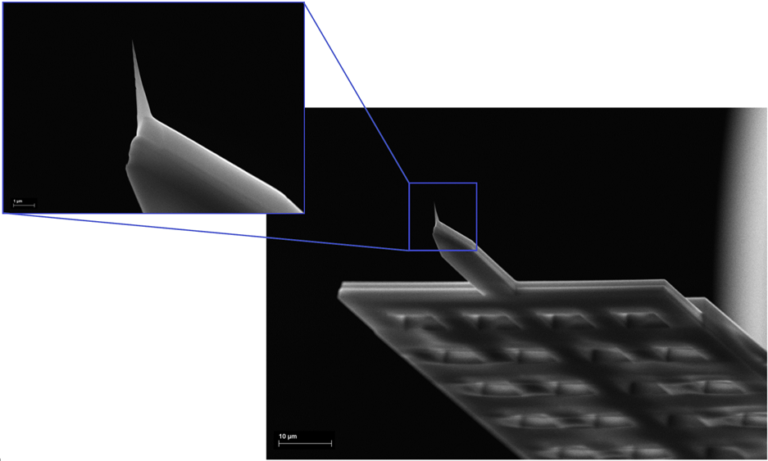

Two different types of tips are available depending on resolution requirements: diamond-like carbon (DLC) tips for high-resolution and general-purpose imaging, and alumina wedge (WDG) tips for coarse imaging, training and step height measurements.

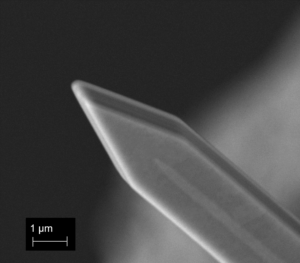

High-Aspect Ratio Diamond-Like Carbon (DLC) Tips

Ideal for general imaging and for demanding applications.

Our DLC tips offer excellent lateral resolution with a tip radius of <20 nm. DLC is a durable material that enables hundreds or thousands of scans without noticeable degradation in scan quality.

Our DLC tips are tilt-compensated by 15º to provide symmetrical, high-fidelity scans. The DLC tip is >1 µm tall.

DLC is a low surface energy material, meaning that it also offers excellent contamination resistance (against particles, debris, polymer build-up and other contaminants).

| Tip radius | <20 nm |

| Tip height | >1 µm |

| Cone angle | <10º |

| Aspect ratio | >3 |

| Tilt compensation | 15º |

| Tip shape | Conical |

| Tip material | Diamond-like carbon |

Aluminum Wedge (WDG) Tips

Ideal for coarse imaging, training and step heights.

Alumina is a durable material that enables hundreds or thousands of scans without noticeable degradation in scan quality.

The native oxide (alumina) of aluminum is a low surface energy material, meaning that it also offers excellent contamination resistance (against particles, debris, polymer build-up and other contaminants).

| Tip radius (effective) | <150 nm |

| Tip shape | Wedge |

| Tip material | Alumina |

Cantilever Specifications

The tip of the AFM is located at the very end of the cantilever beam. The cantilever on all our chips have the same specifications.

| Shape | Beam |

| Length | 30 µm |

| Width | 6 µm |

| Thickness | 3 µm |

| Resonant frequency | 8 kHz (typical: 7 - 9 kHz) |

| Stiffness | 0.1 N/m |

Frequently Asked Questions

Our AFM probes are securely bonded onto the end of a carrier printed circuit board (PCB), making them robust and durable for extended use. They can be handled by hand, provided the probe itself is not directly contacted or subjected to mechanical stress. Under normal usage conditions, the chips maintain their integrity and performance indefinitely.

Imaging with our AFM chips is non-destructive due to the low force tapping mode used and sensitive samples (biological, polymer, etc.) can be scanned with no risk of damage.

Yes! A single AFM chip can be freely used to scan multiple different types of samples during a single imaging session with minimal risk of contamination.

Our AFM chips are integrated with sensors that make our systems fast, easy-to-use and work like magic.

Yes! Our AFM-on-a-chip technology is fully interchangeable between our products.